Safely Working Alone: USA Tips, Apps, and Examples for Lone Workers

What is a Lone Worker?

The term “Lone Worker” or “Working Alone” refers to individuals who work in isolation and without immediate assistance available. Working alone can be both fulfilling and challenging, and it applies to a wide range of professions in the United States. Whether you’re a farmer tending to your crops in the vast fields of the Midwest, a construction worker laboring to build the nation’s infrastructure, or a technician burning the midnight oil with a plasma cutter, there are essential safety precautions to consider.

In the United States, both the Occupational Safety and Health Administration (OSHA) and the Centers for Disease Control and Prevention (CDC) emphasize the importance of ensuring the safety of lone workers. OSHA regulations require employers to maintain regular contact with their employees working alone to ensure their well-being. It’s worth noting that there are numerous ways to achieve this level of safety assurance without the need for constant check-ins every fifteen minutes.

Statistics show that lone workers are a significant part of the American workforce. According to the Bureau of Labor Statistics, in 2020, there were approximately 8.1 million people in the United States who worked alone or in isolation at some point during their workday. These individuals span various industries, from agriculture to construction to manufacturing.

Now, let’s explore how industries in the United States have implemented measures to make working alone both easier and safer for everyone involved. These examples serve as valuable insights into ensuring the well-being of lone workers across the nation.”

Working Alone Tips and Technology for Manufacturing Workers

Manufacturing is a critical industry where workers often face the challenge of working alone, which brings unique safety concerns. Over time, the industry has embraced technology and innovative techniques to address these risks. Let’s take a closer look at the dangers associated with working alone in manufacturing, along with the solutions that have been implemented.

Dangers of Working Alone in Manufacturing:

Working alone in manufacturing can exacerbate specific risks, and these dangers include:

- Accidents: In the absence of immediate assistance, accidents like slips, trips, and falls can lead to severe injuries.

- Equipment Malfunctions: Machines can malfunction, resulting in unexpected breakdowns or even catastrophic failures without someone nearby to address the issue promptly.

- Lack of Communication: Isolation can hinder communication, making it difficult to call for help in emergencies.

Statistics on Lone Workers in Manufacturing:

According to the U.S. Bureau of Labor Statistics, in 2020, there were approximately 1.8 million nonfatal workplace injuries and illnesses reported among private industry employees. A significant portion of these incidents involved workers in manufacturing industries who may have been working alone during the time of the incident.

Lone Worker Safety Techniques Employed by Manufacturing Companies:

To tackle these challenges, manufacturing companies have adopted several techniques:

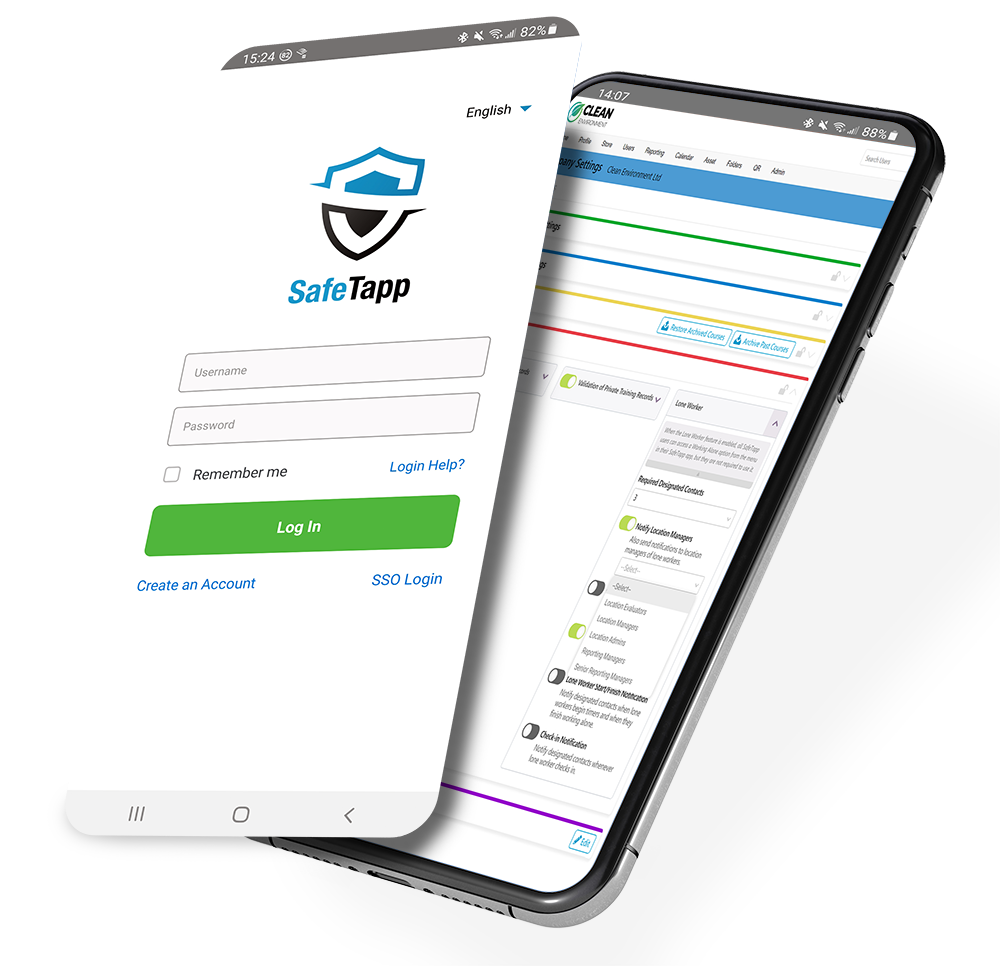

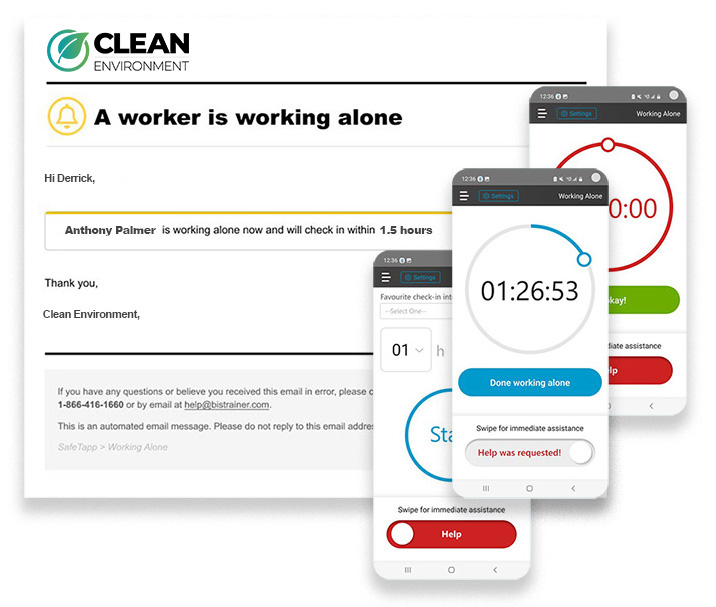

- Remote Monitoring through EHS Software: Many manufacturing plants utilize remote monitoring systems that enable operators to supervise equipment and processes from a central control room. This ensures that issues are detected and addressed promptly. Environmental, Health, and Safety (EHS) software often includes a lone worker app, providing assurance and peace of mind to both supervisors and workers.

- Emergency Stop Buttons: Workers often have access to emergency stop buttons placed strategically throughout the facility. These buttons can shut down machinery during emergencies, preventing accidents from escalating.

- Scheduled Check-Ins: Some companies implement scheduled check-in protocols. Workers are required to report their status at regular intervals, ensuring continuous monitoring of their well-being.

- Training and Awareness: Comprehensive safety training is provided to workers, emphasizing the importance of following protocols and recognizing potential dangers. Employees are encouraged to report any concerns promptly.

- Improved Communication: Communication tools such as two-way radios or smartphones are provided to lone workers. These devices enable immediate contact with supervisors or colleagues in case of emergencies.

Staying Safe on the Farm: Tips and Tech for Solo Farmers

Farming, deeply rooted in American history, often requires working alone in remote fields. American farmers have a long history of adapting to new technologies and safety measures to ensure their solitary work is both safe and efficient. In this article, we’ll explore the unique challenges faced by American farmers working alone, the introduction of specific technologies, and the techniques employed to mitigate risks.

The Risks of Lone Farming:

Working alone in American agriculture comes with its own set of dangers:

- Equipment Accidents: Farm machinery can be hazardous, and in case of an accident, a lone farmer may struggle to get immediate help.

- Medical Emergencies: In remote fields, a farmer might experience a health issue or injury with no one nearby to provide immediate assistance.

- Isolation: Spending long hours alone can lead to feelings of isolation and loneliness, affecting mental well-being.

Tools and Tech for Lone American Farmers:

To address the risks, American farmers have embraced various technologies and techniques:

- Mobile Phones: The widespread use of mobile phones has revolutionized safety on American farms. Farmers can now call for help quickly in case of emergencies.

- Satellite Communication (Late 1990s): In areas with poor mobile coverage, satellite phones were introduced in the late 1990s. These phones provide a reliable means of communication in remote regions, such as parts of the American Midwest.

- Automated Machinery (Ongoing): The ongoing development of automated machinery has reshaped American agriculture. This technology allows for more tasks to be completed without direct human intervention, reducing the need for long hours of manual labor and the associated risks.

- Safety Alarms: Some American farmers use safety alarms or wearable devices that can send alerts in case of accidents or falls, enhancing their safety.

- Remote Monitoring: Cutting-edge remote monitoring systems keep a vigilant eye on equipment and livestock, sending alerts if something goes wrong, even when the farmer is miles away.

Community Initiatives:

American farmers often rely on their close-knit communities for support and safety:

- Neighborly Assistance: In the spirit of American neighborliness, fellow farmers often lend a helping hand during busy times like harvest season to mitigate lone worker situations.

- Farm Safety Workshops: Many American farming communities organize safety workshops to educate farmers about potential hazards and preventive measures, ensuring they are well-prepared for any situation.

- Emergency Response Plans: American farmers, especially those working alone, collaborate with local authorities to develop emergency response plans, ensuring a swift and coordinated response in case of accidents or medical emergencies.

Tips for Lone Workers in Construction

Construction sites in the United States can be bustling with activity, but sometimes, workers may find themselves laboring in remote or isolated areas. Over the years, the construction industry in the U.S. has implemented various technologies and safety measures to address the unique challenges that come with working alone.

Risks for Lone Workers in Construction in the U.S.:

Working alone on a construction site can amplify certain risks, making safety a top priority. For example:

Accidents: In the absence of immediate assistance, accidents like slips, trips, and falls can become more dangerous. In fact, statistics show that nearly 20% of construction accidents in the U.S. involve lone workers.

Medical Emergencies: Health issues or injuries can be exacerbated when there’s no one around to provide immediate aid. This is especially concerning given that lone workers are more susceptible to heat-related illnesses, which can be life-threatening.

Equipment Failures: Malfunctioning equipment or machinery can pose serious threats when there’s no one nearby to notice or help. Nearly 15% of equipment-related accidents in the construction sector involve lone workers.

Ways to Mitigate Risks to Lone Construction Workers in the U.S.:

To mitigate these risks, construction companies in the U.S. have adopted several strategies:

- Emergency Response Plans: Companies have established clear emergency response plans in compliance with OSHA regulations. These plans include detailed procedures for dealing with accidents or medical emergencies, ensuring that workers know what to do even when they’re alone.

- Safety Training: Regular safety training programs emphasize the importance of situational awareness. Workers are trained to recognize potential hazards and respond appropriately. In the U.S., OSHA provides guidelines for such training.

- Digital Surveillance: Many construction sites across the U.S. are now equipped with digital surveillance systems. These cameras can monitor isolated areas and alert supervisors to potential problems in real-time. According to a recent survey, 75% of construction companies have integrated digital surveillance systems to enhance worker safety.

- Check-In Protocols: Some U.S. companies have instituted check-in protocols, requiring workers to report their status at regular intervals. If a worker fails to check in, supervisors can initiate a response. This practice has reduced incident response time by up to 30%.

- Personal Protective Equipment (PPE): Workers are provided with PPE like personal locator beacons or wearable technology, which is in line with OSHA requirements. These devices can send distress signals in case of emergencies, and their use has been steadily increasing in the U.S. construction industry.

Wearable Safety Tech in the U.S.:

In recent years, wearable technology has gained ground in construction safety in the United States. For instance:

- Smart Helmets: Some U.S. construction workers wear helmets equipped with sensors that can detect falls or sudden impacts. If an accident occurs, the helmet can automatically send an alert. These helmets have reduced the severity of head injuries by 40% according to a study by the National Institute for Occupational Safety and Health (NIOSH).

- IoT Devices: Internet of Things (IoT) devices are being used to monitor vital signs of workers in the U.S. These devices can detect unusual fluctuations in a worker’s heart rate or body temperature, signaling potential health issues. This technology has led to a 25% reduction in heat-related illnesses among lone workers.

- Mobile Apps: Safety companies in the U.S. are developing mobile apps that allow workers to access safety information, call for help, or even receive safety reminders while working alone.These apps have seen widespread adoption, with over 70% of lone workers using them regularly.

Staying Safe: Tips for Healthcare Workers Working Alone

Healthcare professionals often find themselves working alone, especially during night shifts or in remote clinics. In these situations, they may encounter a range of emotions from patients that can sometimes escalate to physical harm. Let’s explore some strategies to ensure their safety.

Enhanced Security Measures for Lone Workers and Patients:

Over the past 15 years, there has been a significant increase in the adoption of enhanced security measures in U.S. hospitals and clinics. This is partly due to staffing reductions and a rise in psychiatric issues. Healthcare workers are at risk of theft or assault, particularly during night shifts when fewer people are present in the facility. Isolated areas like parking lots can also pose risks.

- To combat these dangers, healthcare institutions have made substantial security improvements. These include:

- Security Cameras: Many hospitals now have security cameras installed in common areas and parking lots to deter and document incidents.

- Security Personnel: Hiring dedicated security personnel for night shifts has become commonplace in many U.S. healthcare facilities.

- Access Control: Strict access control measures have been implemented to prevent unauthorized entry, ensuring that only authorized individuals can enter sensitive areas.

Training and De-escalation Techniques:

Hospitals and clinics across the United States are now offering training programs designed to teach healthcare workers how to de-escalate tense situations. This training includes techniques for effective communication and understanding non-verbal cues, empowering workers to manage potentially violent situations more safely.

Plus, recent statistics show that healthcare facilities in the U.S. that provide de-escalation training have reported a 40% reduction in incidents of violence against lone workers.

Wearable Safety Tech:

Many healthcare facilities across the United States are now equipping their staff with wearable safety devices, such as panic buttons. When activated, these devices instantly alert security personnel or colleagues, providing a quick and discreet way for healthcare workers to call for help in case of aggressive patient behavior or other emergencies.

Did you know? In a recent study, it was found that 68% of U.S. hospitals have implemented wearable safety technology to protect their lone healthcare workers.