Managing Your Equipment with Software | Asset Management in 2022

Equipment management software can keep track of all your assets, freeing up your administration for other duties. While connecting equipment to a location, asset, or employee using software, you can set reminders, schedule forms, and produce informative data. Asset software helps and reduces a lot of the hassles associated with fleet management, from audit trails to responsibility.

Maintaining your equipment properly requires rigorous checks. However, this task becomes more difficult with more equipment or the larger your fleet. In order to address this, BIS added asset and equipment tracking software to our Safety Management System.

Software for equipment management can mitigate doubt. The software allows you to keep track of who is in charge of the equipment in real-time and whether it has been charged, oiled, or greased.

This software only requires your field personnel to enter the necessary information, all the tedious details like vehicle numbers, credentials, and authorization can be automatically filled out using the user’s profile. So much of the monotonous writing is done by the software before your team member begins to fill out the pre-trip inspection form.

Monitoring Your Equipment with Software

Nesting your equipment in software allows you to link your equipment to location, user, or workstation so you can easily locate it in your inventory. As a result, you can link a workstation to a drill or a pneumatic bander, removing the need for some administrative tasks while making others as simple as a single button click.

For example, if you’re tracking a drill using BIS Safetap software, you can use printed QR code stickers that once scanned allow staff to begin filling out the digital pre-use or pre-trip inspection forms using Safetap app on their own phones. Once they’ve made sure the drill is operational, they can start working without having to write down their name, the drill number, and numerous other details. They just need to focus on the drill while the software does the rest of the documentation duties. Even locations can be automatically tracked. Not to mention, critical information about the drill can be uploaded instantly. Even something as small as a lost drill chuck key can slow a process, that’s why the instant link with other areas of your work is useful.

The same monitoring principles hold true for anything, including forklifts. You can easily turn your entire fleet into trackable data with data entry you’re more than likely already gathering. You can use data to identify trends, inefficiencies, and even careless use.

Additionally, if a worker is not qualified to use the equipment, it can be programmed to alert them after scanning the code.

It reduces the amount of oversight necessary if every employee is aware of the protocol of scanning first.

We use our system to keep track of all the equipment our remote workers use. Our system can be used to monitor our laptops, desks, and chairs, providing HR with a clear picture of our field assets. With the aid of this software, you can do it just as easily.

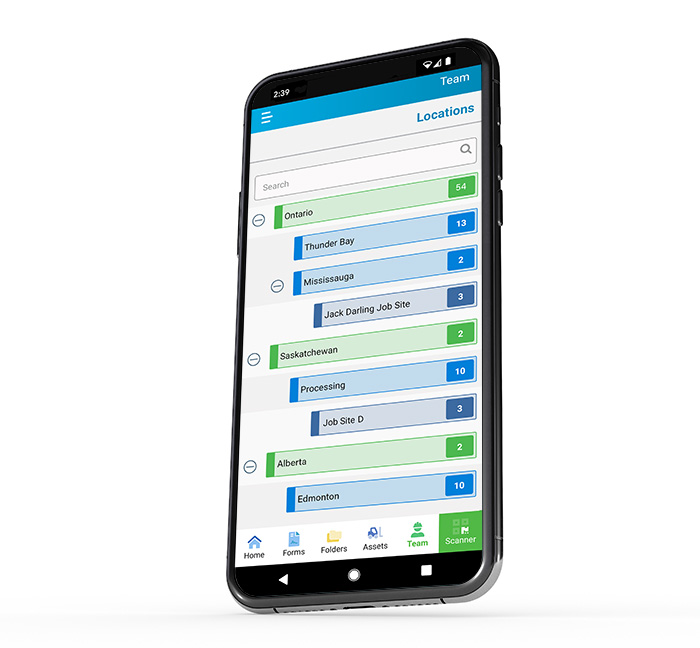

Viewing Your Assets by Location

Another way to manage your equipment is through locations. Sites, warehouses, desks, and even workstations can be nested into a location for ease of access. A location can be divided into as many sections in BIS software as you like.

As an administrator, you can use this app to see who is assigned to each location, whether they have the necessary credentials, whether they are performing equipment checks, and what equipment is nested to each location.

Software Can Be Scrutinized

Audit trails are another component of software that some people overlook. An audit trail is a record of a document’s past, present, and future locations. All of your documents are carefully tracked by software with audit trail functionality, providing a clear trail for any compliance agency to follow. You can quickly give them all the repairs and maintenance you’ve paid for in the past if they ever require it for safety inquiries.

It’s true, you can do a lot with a filing cabinet. However, digital filing is quicker in every regard and can grant access from multiple locations while protecting vital info.

Programmed Maintenance Using Digital Forms and Software

When you only have one truck to maintain, routine maintenance is simple. But even so, a reminder for an oil check, makes things simpler. So, let’s explore software-based scheduled reminders.

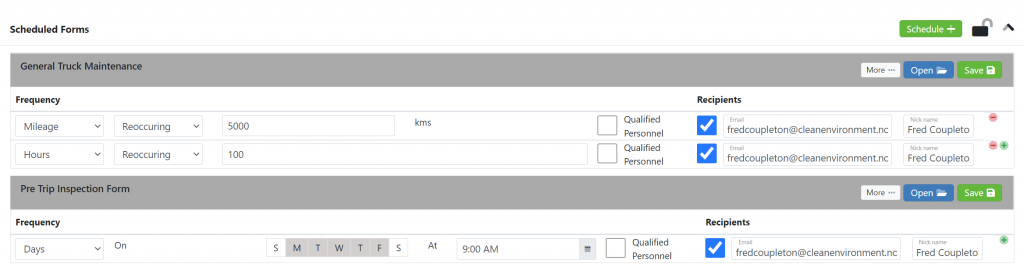

Digital forms are what track your assets. They are completely customizable and can grant you data on any metric your people can document in the field. You can schedule digital forms to activate at specified intervals of weeks, miles, or even hours. As a result, you could perform a daily routine check, start a secondary form once per week, and have a third form appear in the team member’s profile when an oil change is necessary.

Your office can monitor through software-scheduled equipment management:

- Who is using the equipment?

- How many kilometers are on it?

- Where is it located?

- As well as anything else you want to include on the pre-trip digital forms

There are countless options. especially after learning how easy it is to create digital forms that track your equipment. Any numbers that your field personnel have access to can be collected, while the system can export this data in a variety of formats (graphs, charts, excel sheets, etc.).

With the help of this information, you could limit a scheduled mechanic’s work to the necessary vehicles, saving both time and money. Or even send broken equipment off for repairs before it harms someone.

These equipment managing digital forms can be scheduled for drivers and operators, and you can assign entire folders with a single button press. This is especially helpful when reporting incidents let alone tracking equipment. Giving an incident witness access to all the paperwork needed for head office is as simple as granting them access to a folder on the system. At the click of a button they could have all the documentation they require.

Summary of Equipment Management Software

The software can spare businesses tens of thousands of monotonous hours annually. Especially if they require daily paperwork completion from their staff. Additionally, it can simplify checklists and warn you of issues with your fleet. If you own a lot of expensive equipment, you can depend on your staff because you can see their numbers in real time.

With software, you can assess every repair your fleet requires and decide whether to prioritize it for urgent maintenance or not. Anything can be relayed back to you via forms, from headlights to appearance.

The best part is that once everything is set up, software only needs a small amount of administration compared to older systems. If you’re prepared to reduce fleet managing expenses, consider using software.