Course details

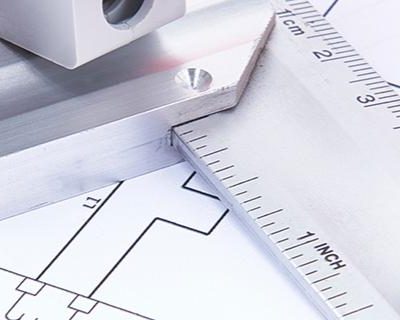

Lockout / Tagout: Put a Lock on Hazardous Energy

This online course helps stop unexpected startups with critical info on OSHA lockout/tagout requirements.

Course Overview

OSHA's Control of Hazardous Energy standard (29 CFR 1910.147) mandates training, inspections, and record-keeping to ensure that workers will not be injured by unexpected start-up or release of energy from a machine or piece of equipment during service or maintenance.

Whatever your role in lockout/tagout, you need to understand the reasons for lockout/tagout and know the established procedures. Lockout/Tagout: Put a Lock on Hazardous Energy is designed to raise your awareness about the importance of lockout/tagout and teach you both when and how to follow the procedures every time they're needed.

After completing this course, learners will be able to:

- Identify sources of hazardous energy

- Describe the three different types of employees recognized in a lockout or tagout program

- Distinguish lockout from tagout

- Explain how to perform lockout and tagout procedures

- Use a group lockout device safely

- Recognize exceptions to lockout and tagout requirements

Topics Covered

- Control of Energy

- Hazardous Energy

- How Accidents Happen

- OSHA Regulations

- Who is Involved

- Lockout Basics

- Definition

- When to Use Procedure

- Steps: Apply Lockout

- Steps: Remove Lockout

- Lock Requirements

- Tagout Basics

- Definition

- When to Use Procedure

- Steps: Apply Tagout

- Steps: Remove Tagout

- Tag Requirements

- Special Cases

- Group Lockout & Group Tagout

- Shift Change

- Vehicle Lockout/Tagout

- Exceptions

- Authorized Person is Unavailable

This course takes approximately 60 minutes to complete

A passing grade of 80% or higher required. Up to 3 attempts are provided.

A certificate will be provided upon the successful completion of this course