Managing equipment and assets effectively is crucial for ensuring workplace safety, compliance, and operational efficiency. For safety managers in high-risk industries, the challenge lies in maintaining real-time oversight of critical tools, machinery, and equipment. Asset tracking software provides a reliable, centralized platform to manage these challenges, reducing risks and improving workplace performance.

Safety managers require practical solutions that not only track assets but also integrate with broader safety strategies. That’s where Asset tracking safety software from BIS Safety Software excels, offering tailored features that address safety and compliance priorities in industries such as construction, manufacturing, and energy.

Why Choose BIS Safety Software’s Asset Tracking Safety Software?

BIS Safety Software provides a comprehensive solution tailored to safety managers’ needs. Its Asset tracking safety software stands out with:

Easy Integration

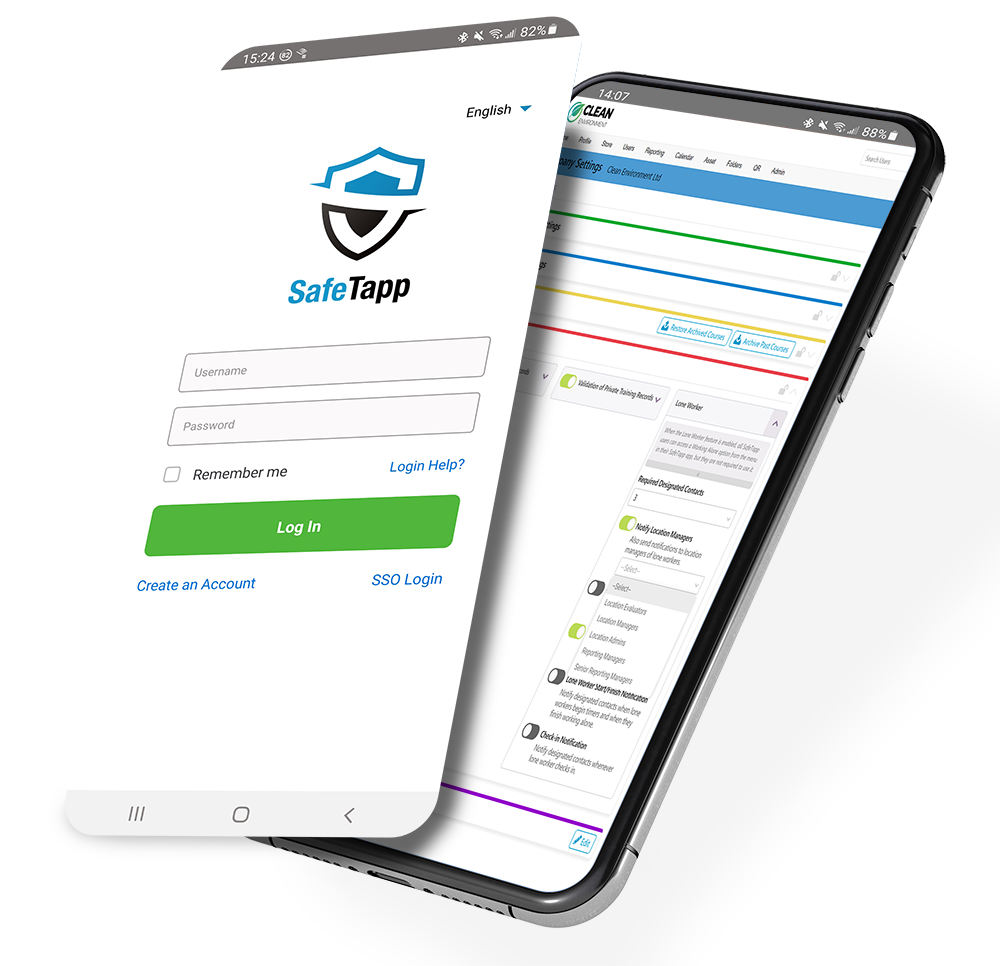

Seamlessly connect with other safety management tools, including incident reporting systems, training platforms, and compliance management solutions. This ensures all your safety processes work together effortlessly, saving time and reducing manual errors.

Scalability

Whether you’re managing assets for a single site or hundreds of locations across different regions, the software scales effortlessly to meet your requirements. It grows with your business, allowing you to monitor, organize, and optimize assets effectively as operations expand.

Responsive Support

Our expert support team is dedicated to ensuring your software implementation is smooth and successful. From initial setup to ongoing optimization, we provide timely assistance, updates, and advice to help you get the most out of the system.

Practical Tips for Safety Managers Using Asset Tracking Software

Conduct Regular Audits: Use the system to periodically verify asset data accuracy and ensure nothing falls through the cracks.

Train Your Team: Provide clear guidance to employees on how to use mobile tools like QR codes for equipment check-ins.

Set Automated Alerts: Leverage maintenance and compliance reminders to stay ahead of safety deadlines.

Use Analytics: Regularly review data insights to identify high-risk equipment or areas needing improvement.

Transform your Safety Processes with Asset Tracking Safety Software

Equip your team with the tools they need to stay safe, compliant, and efficient.