How Digital Safety Forms Are Transforming Compliance Tracking

Compliance rarely fails loudly. It erodes quietly.

An inspection is completed late. A hazard assessment is rushed because the crew is already behind. An audit finding is logged, but the follow up lives in someone’s inbox. On paper, the system exists. In practice, no one has a clear, real-time view of what is actually happening across the organization.

We are seeing this pattern more often as Canadian workplaces become more complex. Crews are spread across regions. Work scopes shift daily. Contractors move between sites. Regulators expect faster responses, clearer documentation, and proof that hazards are being managed, not just recorded.

In that environment, paper-based safety processes do not simply slow organizations down. They create blind spots.

This is why digital safety forms are fundamentally changing how organizations track compliance. Moving inspections, audits, and hazard assessments online is not about convenience or modernization for its own sake. It is about visibility, accountability, and ensuring safety information moves as fast as the work itself.

When safety data flows in real time, issues are identified earlier, corrective actions are tracked properly, and trends become visible instead of buried in filing cabinets. Compliance stops being a rear-view mirror of exercise and starts functioning as an active control.

Why Traditional Compliance Tracking Breaks Down

Paper-based systems were built for a different era of work. Fixed locations. Predictable schedules. Smaller teams. Longer reporting cycles.

That is no longer the reality for most Canadian workplaces.

Across construction, manufacturing, energy, transportation, and logistics, we see the same breakdowns repeatedly:

- Inspections completed but not submitted until days or weeks later

- Illegible handwriting or missing critical information

- Hazard assessments filled out after work has already started

- Audit findings recorded separately from corrective actions

- No practical way to analyze trends or recurring issues

From a regulatory perspective, these gaps matter. Canadian occupational health and safety legislation emphasizes due diligence. Employers must be able to demonstrate that hazards were identified, risks were evaluated, controls were implemented, and those controls were monitored over time.

Paper makes that difficult, especially as organizations grow. Forms get lost. Follow up depends on memory. Data becomes historical instead of actionable. When inspectors ask questions, answers are scattered across binders, spreadsheets, and email threads.

What Actually Changes When Safety Forms Go Digital

Switching to digital safety forms is not just a format change. It restructures how safety information flows through an organization.

Instead of moving slowly from the field to the office, information moves instantly. Instead of being siloed in filing cabinets, it becomes centralized, searchable, and analyzable. Instead of relying on manual tracking and reminders, systems provide structure and accountability.

This shift transforms compliance from a documentation task into a system that actively supports prevention.

Digital forms create a single source of truth for inspections, audits, and hazard assessments. Everyone works with the same information in real time. That visibility alone changes how safety is managed.

Bringing Workplace Inspections Online

Workplace inspections are one of the most common compliance requirements across Canadian jurisdictions. They are also one of the most effective leading indicators of safety performance when they are done properly.

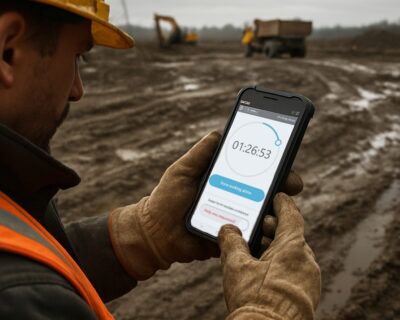

Real Time Submission and Visibility

With digital inspections, results are submitted at the moment the inspection is completed. Safety teams and supervisors no longer wait for paperwork to make their way back to the office. Hazards can be evaluated and addressed while conditions are still current.

We consistently see faster response times simply because the information is available immediately.

Consistency Across Sites and Inspectors

Digital inspection forms can enforce standardized criteria. Required fields must be completed. High risk hazards cannot be skipped. This reduces variability between inspectors and ensures inspections meet regulatory expectations every time.

Consistency becomes especially important when organizations operate across multiple sites or provinces.

Evidence That Strengthens Due Diligence

Photos, videos, and detailed notes can be attached directly to inspection items. This context matters. It shows what was observed, not just that a box was checked. When inspectors ask how hazards were identified and controlled, digital records provide clear, defensible answers.

Paper inspections rarely capture this level of detail.

Modernizing Safety Audits

Audits are often seen as disruptive or administrative, but they provide critical insight into how safety systems are functioning.

Standardized Audit Processes

Digital safety forms ensure audits follow the same structure every time, regardless of who completes them. This allows organizations to compare results across sites, departments, and time periods.

Patterns that were previously invisible start to emerge.

Clear Links Between Findings and Actions

When audit findings are logged digitally, corrective actions can be assigned immediately. Responsibilities are clear. Deadlines are visible. Completion can be verified.

This direct connection between finding and fix is one of the most powerful changes digital systems bring. It closes the loop that paper often leaves open.

Always Audit Ready

With digital records, organizations are no longer scrambling to assemble binders before inspections. Audit history, corrective actions, and follow-up are available instantly. This demonstrates that compliance is part of daily operations, not something prepared only when inspectors arrive.

Improving Hazard Assessments in the Field

Hazard assessments are most effective when they are completed where the work is happening, before tasks begin.

Field Level Hazard Assessments That Reflect Reality

Mobile access allows workers to complete hazard assessments at the job site. Hazards are identified in context, not from memory at the end of the shift. This supports better risk evaluation and more meaningful controls.

We see stronger engagement when workers treat hazard assessments as part of the job, not paperwork to get through.

Adapting as Conditions Change

Work conditions are rarely static. The weather is changing. Equipment arrives. Work scopes expand. Digital hazard assessments can be updated as conditions evolve, keeping controls relevant rather than outdated.

This flexibility is critical in dynamic environments where paper forms quickly become obsolete.

Turning Hazard Data into Trends

When hazard assessments are stored digitally, patterns become visible. Safety teams can analyze recurring hazards, high risk tasks, and locations that consistently generate issues.

This insight supports smarter decisions about training, engineering controls, and resource allocation.

Why Compliance Tracking Improves with Digital Safety Forms

Compliance is not just about having records. It is about demonstrating a process that is repeatable, monitored, and effective.

Digital safety forms strengthen compliance tracking by providing:

- Automatic time stamps that show when activities occurred

- User identification that confirms who completed the work

- Centralized storage that prevents lost or misplaced records

- Searchable data for fast retrieval during inspections

- Linked corrective actions that show follow through

From a due diligence perspective, this level of visibility is difficult to achieve with paper systems.

Supporting Supervisors and Frontline Leaders

Supervisors play a critical role in compliance, yet paper often works against them.

Forms pile up. Issues are tracked in notebooks or emails. Follow up depends on memory. Digital safety forms give supervisors real time visibility into inspections, audits, and hazard assessments.

We see stronger engagement when supervisors can review issues, assign actions, and verify completion as part of their daily workflow rather than administrative cleanup.

Reducing the Administrative Load on Safety Teams

One of the most immediate benefits of safety professionals’ notice is time.

Paper systems require manual data entry, filing, and report generation. Digital systems automate much of this work. Instead of compiling spreadsheets, safety teams can analyze trends, evaluate risk, and focus on prevention.

This shift allows safety professionals to apply their expertise where it matters most.

Using Data to Drive Continuous Improvement

Compliance data has limited value if it sits unused.

Digital safety forms turn raw information into actionable insight. Safety teams can evaluate:

- Common hazards by task, location, or department

- Inspection completion rates and quality

- Recurring audit findings

- Time required to close corrective actions

This data supports proactive decision making rather than reactive responses.

Meeting Regulatory Expectations

Canadian regulators are increasingly focused on systems, not just outcomes. They expect employers to show how hazards are identified, how risks are controlled, and how corrective actions are verified.

According to the Canadian Centre for Occupational Health and Safety, effective hazard identification and documentation are foundational to due diligence. Digital tools strengthen both by improving accuracy, accessibility, and follow through.

When inspectors ask how hazards are managed, digital records provide clear, defensible answers.

Why the Shift to Digital Is Accelerating

Work is faster. Crews are more mobile. Documentation expectations are higher.

Paper-based systems cannot keep up with that reality.

Organizations adopting digital safety forms are better positioned to scale their safety programs, respond quickly to issues, and maintain consistent standards across sites and regions.

From Static Records to Living Safety Systems

The real transformation is not technological. It is operational.

When inspections, audits, and hazard assessments move online, safety becomes more visible, timelier, and more connected to action. Compliance tracking shifts from a historical record to a living system that actively supports prevention.

We see the strongest safety programs use digital forms as the foundation, then reinforce them through training, supervision, and continuous improvement. That is how compliance evolves into performance.